COVID completely shut down combat robotics. Groups totally disappeared for a while. Some never restarted. But it’s hard to keep a good thing down and popularity is rising. But why are we ignoring the spectators?

Beginnings and a Temporary Shut-Down

The BattleBots and Robot Wars television shows introduced millions to combat robotics, but the true growth of the sport came from what happened off-camera: the explosion of smaller weight classes such as antweights (1 lb) and beetleweights (3 lb). These compact categories did more than just shrink the scale of the bots — they radically lowered the barriers of participating, making the sport accessible to students, hobbyists, and new builders around the world.

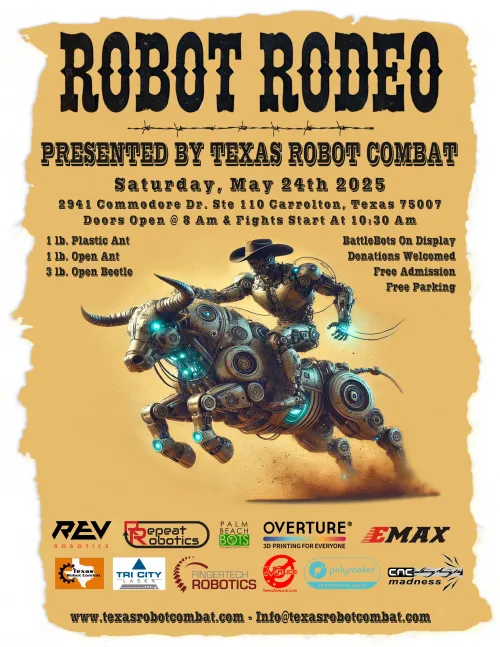

The sport was just gaining traction when COVID shut everything down. The post-COVID resurgence of combat robotics is nothing short of inspiring. After a period of uncertainty, local and regional groups and events are popping up again, with builders eager to push technical boundaries. Yet as events rebuild, there’s a recurring and worrying oversight: we’re still not designing combat robotics events with spectators in mind.

It’s a missed opportunity that could stunt the growth of the sport — again.

The Problem: Builders-Only Mindset

Many events today are understandably builder-centric. They’re meant to be informal, low-stakes environments for teams to test new designs, compete against their peers, and troubleshoot in real time. That’s fine — but not at the cost of ignoring the spectator experience entirely.

Too often, events are held in isolated venues with poor visibility, muffled sound, no commentary, and little to no schedule transparency. To a newcomer — a potential fan, sponsor, or future builder — it’s almost impossible to understand what’s happening, let alone stay engaged.

When someone’s first experience of combat robotics is standing behind a barricade with no idea which bot is which, or worse – little or poor view of the action, you’ve lost them. Maybe forever.

An Event to Remember – Almost

At a tournament I recently attended, the event was well planned for the participants. A large area was chosen for the pits. The action in the arena was even live streamed back to the pit area. It was a great event for builders.

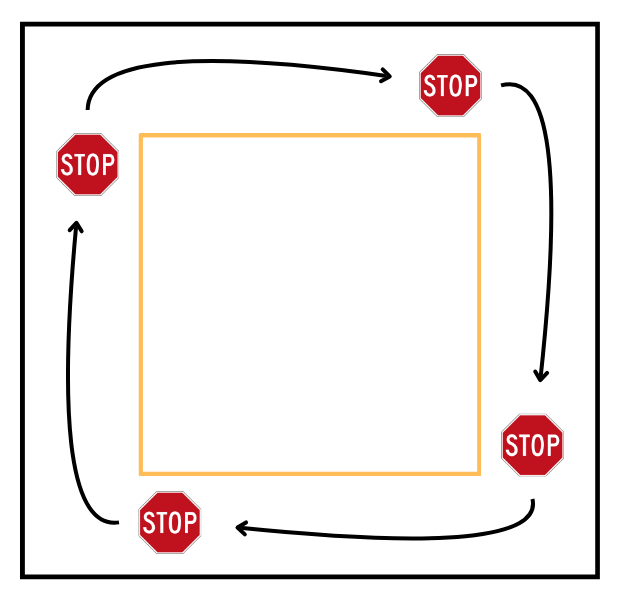

Some thought was given to spectators as play-by-play commentary was provided, but not enough of chairs were available for those wanting to watch the action. Easily, twice that number were standing, stacked on both sides of the seating area, straining to just get a glimpse of the fighting robots. If that was not bad enough, the arena was set up where spectators were only on one side, restricting the number of “front row” seating.

I tried catching as much action as I could, standing in one of the groups on the side. That’s my fault as I arrived late, but after 30 minutes I become frustrated and fell back to the area behind the seats with no view whatsoever of what was going on in the arenas. It was there I started crowd watching. I saw the frustration on many faces, just wanting to see the scrapping bots. Many folks came into the building, only to leave fifteen minutes later after figuring out a clear view to the arenas was not easily obtained. How many potential future bot builders or sponcers were in that group?

After mid day, many of the spectators had cleared out. The seating area was half-full (or half-empty, depending on your mindset). Probably, those remaining were family and friends of the competitors. Those that came to see what this robot combat stuff was all about had left, several probably frustrated by their experience. Thank goodness spectators were not charged to watch.

Now, every event would love to have a problem of overflowing attendance outpacing planning. But too many are planned with just the competition in mind only. If the sport is going to continue to gain momentum, more thought has to be given to spectators.

Why We Must Strive to Develop an Audience?

Combat robotics isn’t just about the battles. it’s about storytelling, innovation, grit, and spectacle. If we want to grow the sport, we can’t treat audience engagement as a “nice to have.” Fancy arena lighting with high-tech timing displays are great, but it doesn’t matter if all the folks can’t see it.

Spectators bring revenue. Whether it’s potential ticket sales, merch, or sponsors — eyeballs are currency. And I don’t know of a combat robotics group in the country that has “too many” resources. Some are fighting to get enough cash just to build an arena or put on a bare-bones tournament. Paying more attention to spectatorship can provide the funds needed to go from a gathering to an event.

Audience members can become future builders. Today’s wide-eyed kid is tomorrow’s driver or tech lead. Even older fans (such as myself) can be inspired by the excitement at a tournament to where they want to take part in the fun. It’s human nature. And as competitors leave the sport for whatever reason, we need new blood to keep the sport rolling.

Also, spectators attract local and regional support. Community interest can lead to partnerships and media coverage which is essential for continued growth.

Least, but certainly not last, there’s noting like a cheering crowd to elevate the matches. Even a low-stakes scrimmage feels more meaningful when a crowd is into it. Vocal crowds can cause any event to be a more memorable experience.

Solutions Aren’t Hard — They’re Just Ignored

I get it – some small groups just don’t have the resources needed for a fancy production. But It doesn’t take a Hollywood budget to make events more spectator-friendly.

Let’s Start with:

- Commentary. Basic play-by-play keeps viewers engaged and informed. The larger events I have attended usually have provided an announcer, but smaller events tend to overlook this detail.

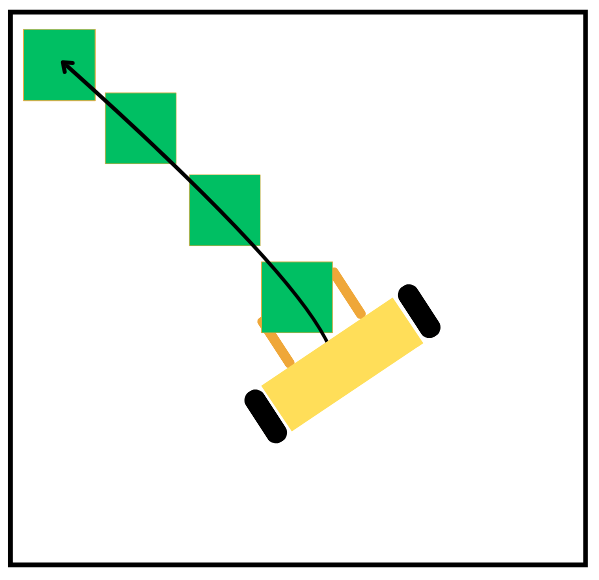

- Live scheduling boards. A cheap TV showing match times and/or brackets makes a huge difference. Many events provide this feed to the participants, but spectators are left out in the cold. We need to keep the spectators engaged and informed.

- Team intros and bot profiles. A program with a little info on the registered bots and builder bios would give the crowd someone to root for.

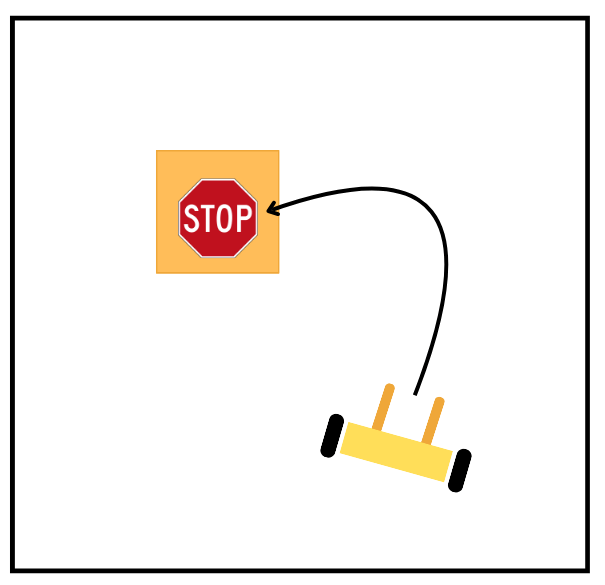

- Live stream onto a screen for all to easily see, especially if the event is seat-challenged. If you can’t give a clear view for spectators, at least get eyes on a screen.

Of course, the above costs money. But I guarantee people would pay a small fee to watch combat robotics if they are provided access to the action. And the probability of bringing friends to the next event is high.

Time to Act

Combat robotics is uniquely positioned at the intersection of education, entertainment, and engineering. But if we keep hiding the sport behind garage doors and warehouse walls, it will never reach its potential.

Tournaments shouldn’t be just about bots in an arena — they should create audiences that care. But they won’t care if they are not provided all the information.

Let’s stop treating spectators as an afterthought. If we want to grow combat robotics sustainably, we need to develop events that cause people to love the sport. To do that they have to see and enjoy the experience. If we can do that, the sky is the limit for combat robotics.

Want more tips for combat robotics electronics, construction, or tournament prep? Subscribe to my newsletter or leave your questions in the comments!

Check out more info on combat robotics in my Knowledge Base articles.