3D printing has changed the way we think about production and creativity. From its beginnings in the 1980s to the cutting-edge technologies used today, the history of 3D printing is a story of vision, experimentation and innovation. In this blog post, I will explore the key milestones and those responsible for the development of 3D printing technology and the companies that followed.

Dr. Hideo Kodama & Chuck Hull

The story of 3D printing began in 1981 when Dr. Hideo Kodama of Nagoya Municipal Industrial Research Institute, Japan, filed a patent for a rapid prototyping system. Dr. Kodama had successfully demonstrated the process for creating 3D plastic parts by photo-hardening polymers with UV exposure.

However, the first significant breakthrough came when Chuck Hull, the co-founder of 3D Systems, created the first 3D printed part on March 9, 1983, through a process he called stereolithography. Hull developed this technology after working for many years developing chemicals and then switching jobs to find himself working with ultraviolet light. Hull filed for a patient for stereolithography apparatus (SLA) in 1984. His technique used ultraviolet light to cure liquid resin layer by layer, creating three-dimensional objects. Today’s 3D resin printers are a direct descendant of Hull’s efforts.

In 1988, 3D Systems marketed the first commercial 3D printer, the SLA-1, which allowed designers and engineers to create prototypes quickly and efficiently. This was not only the first commercial 3D printer but was also the foundation for the additive manufacturing industry.

Dr. Carl Deckard (Go Longhorns!)

The 1990s included a surge of innovation in 3D printing technologies, with the introduction of new methods including selective laser sintering (SLS) and fused deposition modeling (FDM).

SLS, developed by Dr. Carl Deckard utilized a laser to fuse powdered materials, allowing for greater design complexity and material versatility. Deckard initially came up with the idea as an undergraduate at the University of Texas at Austin. He continued developing the technology as a Masters and PhD student with the help of Dr. Joe Beaman, a professor at UT Austin. After several years of trial-and-error, Deckard’s machine was capable of manufacturing real parts.

In 2012, Deckard co-founded Structured Polymers LLC, a company that develops novel polymers for SLS machines. He died at the age of 58, on 23 December 2019.

Scott Crump

Also in the 90s, Scott Crump co-founded Stratasys and patented the FDM process, which involved extruding thermoplastic filaments to build objects layer by layer.

Crump invented the technology known as FDM or Fused Deposition Modeling, patented it 1989, and founded Stratasys, Inc with his wife Lisa. Mr. Crump was CEO of the company for 25 years until the company’s merger with Objet Ltd. in 2012.

3D printing began to gain traction beyond prototyping. Industries started exploring its potential for creating end-use parts, molds, and even medical implants. The first 3D-printed organ model was created in 1999, showcasing the technology’s potential in the medical field.

Adrian Bowyer & RepRap

The start of the 21st century marked a turning point for 3D printing, as 3D printing became more accessible to businesses and individuals.

A major step in that direction happened in 2004 when Adrian Bowyer initiated the RepRap project. The program was started at the University of Bath in the United Kingdom. RepRap was an open-source initiative aimed at creating a 3D printer that could produce most of its own parts. This essentially making affordable 3D printing technology widely accessible. This open-source initiative sparked a wave of interest in DIY 3D printing and led to the development of affordable desktop printers.

MakerBot

In 2008, MakerBot was founded, introducing the first user-friendly 3D printer for hobbyists and makers. MakerBot Industries, LLC was an American desktop 3D printer manufacturer company headquartered in New York City. It was founded in January 2009 by Bre Pettis, Adam Mayer, and Zach “Hoeken” Smith to build on the early progress of the RepRap Project. It was acquired by Stratasys in June 2013. As of April 2016, MakerBot had sold over 100,000 desktop 3D printers worldwide.

This accessibility of 3D printing fueled a global makers movement, inspiring individuals to create their own designs and share them online through platforms like Thingiverse.

Mainstream Adoption and Innovation

As 3D printing technology continued to evolve, it found applications in a growing number of industries. In 2012, the first 3D-printed car was unveiled by Local Motors, showcasing the potential for additive manufacturing in the automotive sector. Meanwhile, the healthcare industry began using 3D printing for custom prosthetics, dental implants, and even bioprinting tissues.

Josef Prusa

Prusa Research was founded as a one-man startup in 2012 by Josef Prusa, a Czech hobbyist, maker and inventor. Today, Prusa Research has grown to a 700+ team shipping more than 10,000 Prusa printers per month to over 160 countries directly from Prague.

Watch this YouTube video to find out how Prusa Research was born and what they achieved within only 10 years.

Creality 3D

In 2014, four friends in Shenzhen, China – Chen Chun, Ao Danjun, Liu Huilin, and Tang Jingke, started Creality 3D in a small workshop. Nowadays, the company consists of more than 550 employees occupied in offices located in Beijing, Shanghai, Wuhan, and Huizhou. The company now sells more than 50,000 3D printers annually.

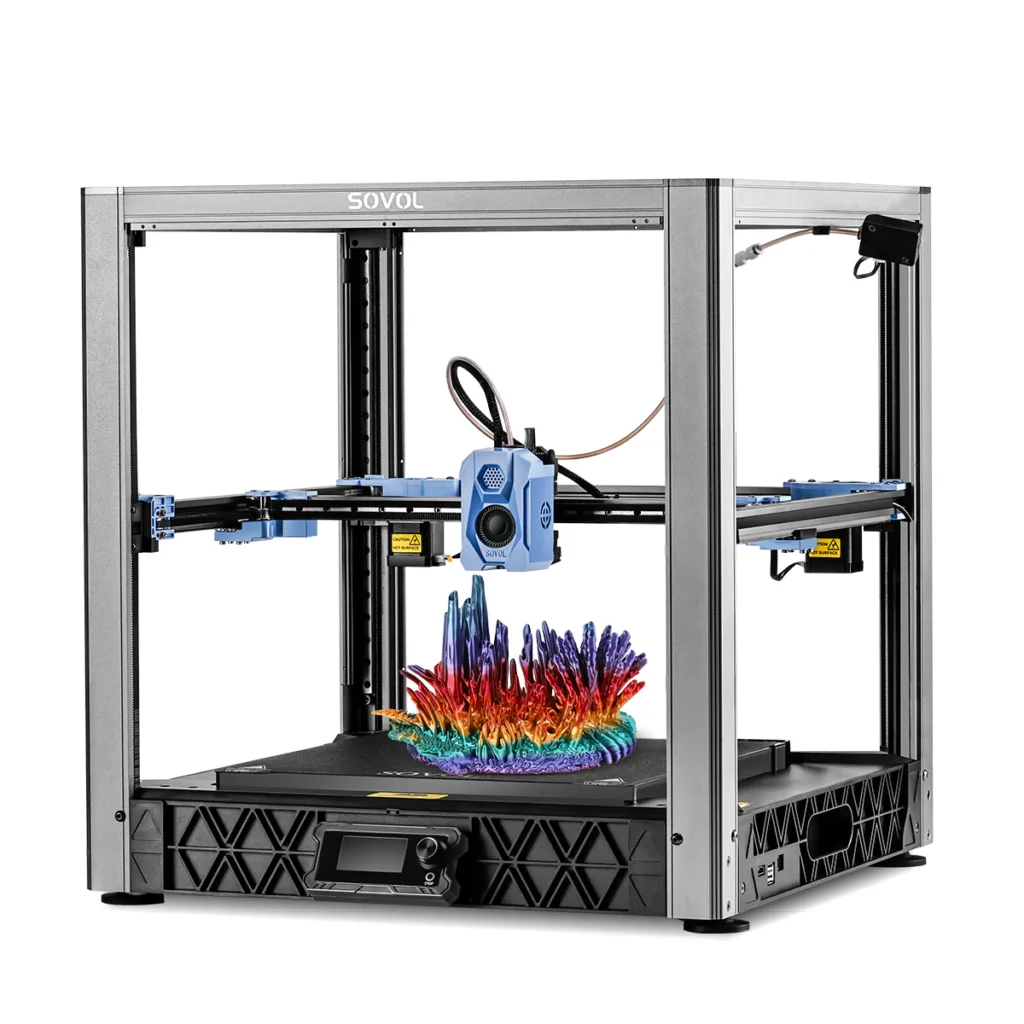

Sovol

In 2018, Sovol, based in Shenzhen, China, was founded with the goal of making 3D printing technology accessible to everyone. The company started by producing filament, accessories, and parts. In 2019, Sovol released its first printer, the SV01. Sovol’s products are designed to be open source, allowing users to customize and enhance their printers. Sovol’s products are known for being affordable, well-made, and easy to use. In 2024, Sovol released its latest printer, the SV08.

Sovol SV08

Bambu Lab Emerges

In 2020, a team of engineers from DJI, a Chinese tech giant that dominates the drone market, started Bambu Lab. Like Sovol, the company is based in Shenzhen, China. Bambu Lab now has locations in Shanghai and Austin, Texas.

The company’s first product, the Bambu Lab X1, was launched on Kickstarter in 2022. The X1 was named one of the Best Inventions of 2022 by Time Magazine. In just a very short time, Bambu Lab has become a major player in the consumer 3d printer business, offering high-quality printers at a fraction of the cost of more expensive systems.

A Future of Possibilities

As we move past 2024, 3D printing continues to evolve at a rapid pace. Sustainability has also become a focal point, with researchers exploring biodegradable materials and closed-loop recycling systems for 3D printing. The future is bright, with potential applications in construction, aerospace, fashion, and even food.

Conclusion

The history of 3D printing is a testament to the tireless pursuit of innovation. From its start in the 1980s to its status today, 3D printing has changed the way we design, create, and manufacture. As we look ahead, it’s clear that the possibilities for 3D printing are endless. Its impact on our world will only continue to grow. The journey of 3D printing is just beginning so let’s embrace the future of creativity and innovation together!

Check out 3D printers on my Shop pages